5 Reasons to choose a chemical etching on stainless steel

Modern marking is a solution intended for professionals for the manufacture of personalized plates. In addition, there are several types of engravings such as acid etching, laser, and screen printing … While the metals concerned are mainly: Copper, brass, aluminum, and stainless steel.

This solution can therefore be adapted to many supports. That’s why it sometimes seems difficult to choose the right material that goes perfectly with your chemical etching.

If you are looking to engrave on a high-quality metal, here is why we recommend chemical etching on stainless steel:

5 – the unique nature of stainless steel:

To tell the truth, there are various grades of stainless steel commonly called stainless steel, and you need to go through a specialist to direct you to the suitable quality of stainless steel, but stainless steel still takes its name from its main characteristic which is the stainless ability meaning that it is very little sensitive to rust. It is also strong in resistance against any aggression such as chemicals because it is protected by the layer of chromium that composes it. This feature makes it the best-performing metal by far!

4– Acid etching on stainless steel: Durability

chemical etching

Stainless steel is used for the manufacture of many objects in your daily life, but it is also present in the professional sectors: mechanical, medical others including the manufacture of medical instruments this is because it resists friction when cleaning, UV, climate change … If you choose the chemical engraving, you ensure a permanent marking lasting forever thanks to its high quality.

3- diverse finish:

Compliance with all standards has become increasingly rigorous in Tunisia, especially in the field of chemical etching marking, which requires a high degree of finesse and precision in the slightest details of your model to obtain good results even on small dimensions.

The chemical engraving allows realizing customized markings which meet the various needs, it can be in hollow or in relief, with a smooth, Matt, brilliant aspect… etc.

2- the possibility of colors for acid etching on stainless steel:

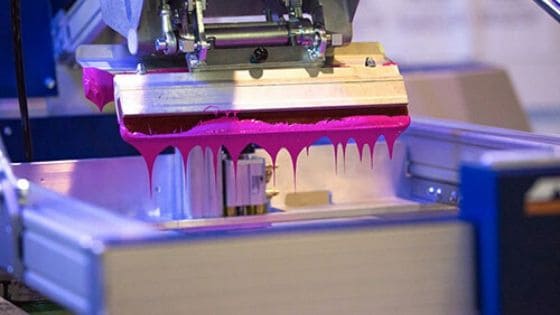

A modern marking sometimes needs a touch of color and if you are considering a custom engraving with several colors all this is possible with the chemical engraving technique that can be more specific with the addition of any colors you want and that will last for decades!

Read also :

1-Return on investment (ROI):

Indeed, the unit cost of an engraved stainless steel plate is high and requires a longer manufacturing time compared to other solutions for the same time frame, that is why this solution is reserved for orders of large or medium quantities.

On the other hand, it will last for a long time, so you will not have to replace it and in the long run, you can recycle it.

Do you have a marking project that uses chemical engraving? Great! Our sales department can advise you, guide you, and even provide you with a free quote! What are you waiting for?

Mohamed

SAC Marquage

All about industrial silk screen printing!

"industrial screen printing"Industrial screen printing is one of the oldest printing methods, having originated in…

The importance of manufacturer’s plate

"manufacturer's plate"The term "manufacturer's plate" is frequently used in the automotive industry. It allows identifying…